LU-2828V-7

![]()

Digitalization

Management of sewing condition by IoT

Digitalization adjustment made possible for core specifications such as thread tension, pitch length, sewing speed, presser foot pressure and alternating vertical movement. Crucial adjustment work are now made simple without excessive experience and skills while reinforcing high quality reproductions. This feature allows sewing machines in a

sewing line to be uniformly set, thereby contributing to stabilization in

product quality.

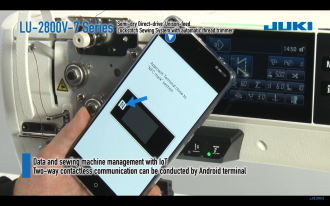

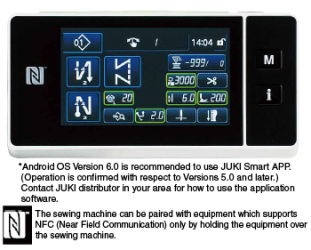

Displayed on Android device

Data displayed on the application software

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software update can be carried out with ease using a USB thumb drive.

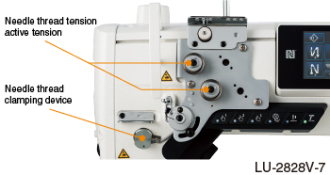

Active tension

Needle thread tension which matches sewing conditions given can be set on the operation panel and stored in memory. The needle thread tension adjustment needs experience. However, for this sewing machine, thread tension data stored in memory is reproducible, thereby reducing the setup time when the product to be sewn is changed.

Example: Needle-thread active tension demonstrates its effectiveness in the topstitching process.

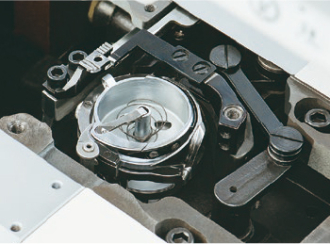

The shorter-thread trimming mechanism

The thread trimming mechanism has been completely renewed. The industry's shortest remaining thread length achieved by trimming the thread close to the fixed knife at the last stitch (condensed stitch). (The length of remaining needle thread is 5 mm)

It also comes standard with thread catcher of sewing start which reduces the work for thread picking and avoids damage to the fabric when picking with knife.

※LU-2828V-7 applicable

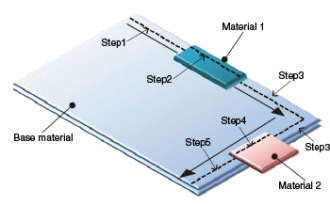

Multi-layered part detection function

Multi-layered parts of material which occur in the case two or more plies of material are sewn or different kinds of material are sewn can be detected by the multi-layered part detection function to change over the stitch length, thread tension, presser foot presser and amount of alternate vertical movement to those that have been predetermined for sewing those parts of material.

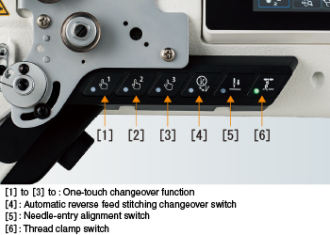

6-string switch

The sewing data (stitch length, needle thread tension, amount of alternate vertical movement, presser foot pressure and sewing speed) can be changed easily with the one-touch changeover switch to obtain the ones that have been elaborated according to sewing conditions.

Four different one-touch functions can be assigned to six-gang hand switches [1] to [6], touch-back switch and jog dial, at the maximum.

(*For the initial settings, the one-touch functions are assigned to 6-gang switches [1] to [3].)

Jog dial

The operator is able to turn the main shaft (for moving the needle bar up and down) only with the jog dial without stretching his/her arm to the hand-wheel. When the jog dial is pushed, it can be used as 1/2 needle-stitch correction switch (one touch function).

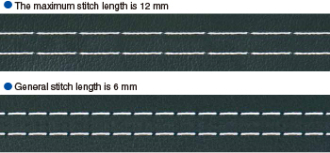

The maximum stitch length is 12 mm

This model is the most-desired sewing machine for sewing furniture such as sofas. It is best-suited to topstitching with a stitch length of maximum 12mm pitch. During the topstitching process, the longer distance from the machine arm to the bed, in particular, effectively demonstrates the machine's improved workability.

※LU-2860V-7 applicable

Polygonal shape stitching function

For settings corresponding to continuous sewing conditions (polygonal shape stitching function), more beautifully finished seams are produced by using various functions (custom-pitch setting function, reverse-feed stitching function).

Smart Devices Options

■Cover Sensor

In a situation where the cover is open, an error will be displayed and stop the operation. (Eye guard, Bed slide, Handwheel applicable)

■Skip Stitch Detector

Stitch skipping is detected during sewing. This helps lighten the operator's inspection work load and also prevents defective products from being shipped. In the case where a skipped stitch is detected, the buzzer sounds up and the sewing machine stops.

■Bobbin Thread Remaining Detector

The buzzer sounds up when the amount of thread remaining on the bobbin reaches a predetermined length. It is also possible to stop the sewing machine at this point.