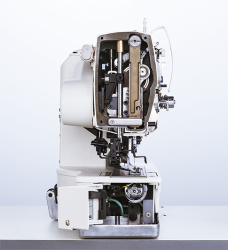

LBH-1790AN

![]()

2-way communication

The NFC-equipped LCD panel enables easy horizontal transfer of sewing patterns and sewing data to other sewing machines using Android tablet.

The operation panel display (operation screen, error screen, and maintenance screen) is available in a total of 14 languages, allowing operators and maintenance personnel to select the language that best suits their needs.

Active tension

Needle thread tension for sewing parallel and bartacking sections of buttonholes can be separately controlled through the operation panel and stored in memory according to various sewing conditions (e.g., type of thread, type of material and sewing speed).

The machine is able to change the needle thread tensions at the parallel and

bartacking sections of the buttonhole, to produce a beautiful buttonhole shape. This capability helps greatly in preventing thread breakage.

Needle thread tension is activated at the beginning and end of sewing.

This prevents unthreading of the needle thread, and thread fraying that is likely to occur at the beginning of sewing.

Thread tension for basting stitching can be specified separately.

Cloth cutting knife

Pulse motor drive makes it possible to cut fabric at an appropriate speed according to fabric thickness.

In addition, the noise when cutting cloth has been greatly reduced compared to the conventional magnet drive type.

Various stitch patterns

This has 31 patterns of buttonhole shapes as standard.

Up to 99 patterns can be stored and freely selected from the operation panel.

For example, "Pattern No. 31", which sews only the basting stitch and fabric cutting, can be used as a guide when buttonholing by hand, making it ideal for high-end customers and contributing to efficient, high-quality buttonholing.

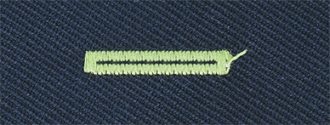

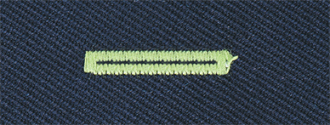

Basting stitch

With or without of basting stitch and the number of basting stitches around(selectable from 1 to 9 arounds) can be set on the panel.

The basting stitch which stitches around the circumference of buttonhole before buttonholing increases the strength of the stitching area, and is particularly effective for stretchy materials such as knit fabrics.

Multiple knife-dropping function

Thanks to the multiple knife-dropping function, it is no longer required that the knife be changed at the time the buttonhole size is changed.

The number of knife dropping times can be automatically set according to the buttonholing size in cases where the buttonhole size is frequently changed for small-lot productions or during the cycle sewing of buttonholes that are different in size.

Easy to change sewing setting

Digitalization allows easy switching of sewing settings such as purl and whip stitching, single stitching and double stitching, etc.

Shorter-thread remaining mechanism

Active tension reduces the amount of thread remaining less than 2 mm at the end of sewing.

This also prevents defects caused by accidentally damaging the sewn fabric with scissors during thread trimming.

(LBH-1790ANB)

Throat plate for 10mm

The throat plate as standard is for a maximum throwing width of 4 mm or 5 mm.

However, it is possible to install an optional component that can handle a maximum throwing width of 10 mm.

You can sew wide buttonholes or your own *original buttonholes.

*PM-1 is separately required to create your own buttonholes.

Specification