DDL-900C

![]()

E-FLeCS

Electric Feed Length Control System (E-FLeCS)

With the stepping motor used to control the feed mechanism, the feed pitch is adjusted with the color LCD touch panel control instead of the conventional pitch dial.

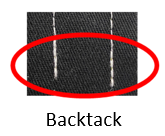

Back Tack

With motor control, the backstitching at the beginning and end of sewing overlaps perfectly to achieve clean seams.

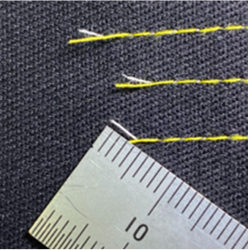

Condence Stitch

Condence stitch make it possible shorter thread remaining 3.5mm or less.

Design Stitch

Digitalized feed pitcheds dramatically widen the range of stitch designs.

Double moving knives

Double moving knives makes it possible to cut thread just under the needle, so that realize shorter thread remaining 3.5mm or less.

Auto&Knee lifter

Shared motor power with the thread trimmer now makes it possible to provide the auto lifter as standard. A highly demanded knee-lifter is also provided as standard for further enhanced workability.

Operation Panel

DDL-900C‘s operation panel is color LCD with touch panel. It is easy to see and operate.

Oil sealing system

DDL-900C has adopted the “Oil Sealing System” which is integrated into the sewing machine bed.

Elimination of oil stains on sewing products

Oil is stored in the oil-shielded made of highly rigid aluminium die cast which is integrated into the machine head and provides increased cooling performance. The oil-shielded has increased sealing performance as compared with a plastic oil tank and effectively prevents oil leakage and tank breakage.

Window for checking the amount of oil

It is possible to check the amount of oil easily since "oil amount window" has been adapted on machine head.

(Reccomend Oil: JUKI No.7)

Promotion VIDEO

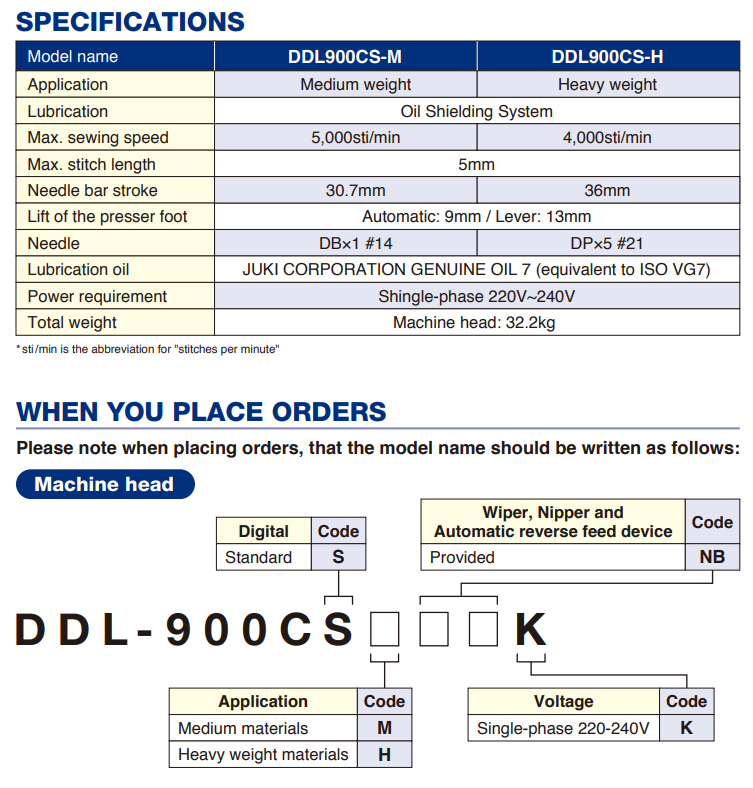

Specification