AMS-224EN4530R/AW3

![]()

AW3

Productivity enhanced

AW3 changes the bobbin thread while the operator is replacing the material, which reduces the down-time for bobbin replacement. As a result, the productivity will be enhanced.

Reduction of defective rate and re-sewing

Tthe operator neither need to worry about the timing of changing the bobbin nor have to replace the bobbins by himself/herself. Moreover, only two bobbin cases are used alternately in repetition. It means that uniform bobbin thread tension and consistent seam quality are achieved without requiring additional adjustment of the bobbin thread tension.

Reduction of the bobbin thread consumption

When loading a sewing pattern, AW3 automatically calculates the bobbin thread amount to be consumed to sew the next sewing pattern and determines whether the sewing machine can complete the sewing of the pattern with the bobbin thread amount remaining before starting sewing. If the remaining amount of the bobbin thread is not enough for sewing the loaded sewing pattern, AW3 will automatically change the bobbin to another bobbin that is fully wound with thread.

Reduction of operator’s fatigue

Since AW3 automatically feeds the bobbin thread, it is no longer necessary for the operator to get under the machine to manually change the bobbin thread. This contributes to the reduction of the operator's fatigue.

Full automation achieved by AW3

Full automation has been achieved with a combination of robotic arms. Originally, it required manual operation for bobbin replacement even after installing robotic arms. AW3 will help you achieve full automation environment.

Active tension

With the active tension, pinpoint changes in the needle thread tension during sewing are enabled. The needle thread tension, therefore, can be set in conjunction with the material thickness and can be corrected according to the direction of sewing on a stitch-by-stitch basis through the operation panel. Since the needle thread tension is reproducible, supporting a broader range of sewing conditions, the time required for setup changing upon process changeover can be reduced.

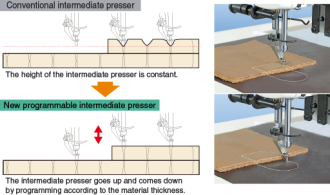

Intermediate presser foot

With the programmable intermediate presser, the height of the lower dead point of the intermediate presser can be set according to the material thickness, thereby not only preventing troubles in sewing such as stitch skipping and thread breakage, but also protecting the sewing product from being damaged by the presser. The height setting can be changed with ease even during sewing. The machine finishes beautiful uniform seams free from stitch skipping even on multiple parts of the material by the ideal combination of the active tension and programmable intermediate presser.

Hook driving shaft pulley

Hand pulley & Hook driving shaft pulley

Hand pulley:With the hand pulley which is laid out on the machine arm, not only the height of the needle bar or intermediate presser but also the needle entry point at the time of data programming can be adjusted with ease

Hook driving shaft pulley:A pulley is also provided on the lower part of the machine. This enables easy adjustment of the hook.

IP420

It is provided with a wide screen and programmable functions. Data can be input/edited while visually checking the needle movement.

The color LCD unit displays sewing data such as stitch shape, needle thread tension, enlargement/reduction ratio, sewing speed and the number of stitches at a glance.

Semi-dry head

JUKI’s advanced dry technology, which is utilized in a number of our sewing machine models, protects your products from being stained with oil.

Frame:dry

Hook:minute quantity lubrication