AC-172N-1790AN

![]()

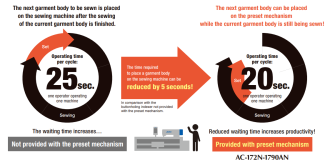

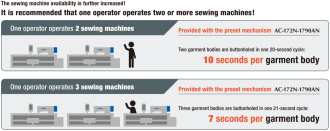

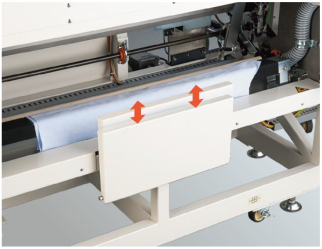

Preset mechanism

The preset mechanism enables the next body to be set (overlap operation) during the buttonholing process, making it possible to effectively utilize the waiting time during the buttonholing process and achieve high productivity.

*The preset mechanism is a function that allows the next piece of fabric to be set while the buttonholing is in progress.

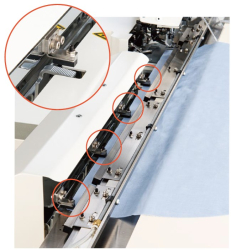

Sub-clamping device

A new mechanism to prevent fabric misalignment (misalignment in position) during preset fabric delivery ensures stable sewing quality even with vertically striped fabrics.

In addition, fabric presence/absence detection eliminates machine mis-starts.

Indexer

The pulse motor controls the cloth feed rate in 0.1mm increments for accurate and reliable cloth feeding.

(Number of button holes: 1 to 20, Number of patterns stored: 20)

A function that synchronizes the movement of the conveyor with that of the sewing machine during sewing is provided as a standard feature, enabling accurate and reliable feeding of cloth without sagging of the fabric to be sewn.

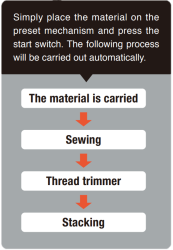

Stacker

A stacker device that automatically stacks the garments after buttonholing eliminates the need for the worker to place the garments, thereby increasing work efficiency and further improving productivity.

IP-420 panel

A color LCD touch panel with a larger screen displays sewing data such as stitch shapes and needle counts in an easy to understand, and an input function enables input and editing operations while viewing the bottom of a needle.

The operation panel is equipped with a CompactFlash* and USB port as standard, allowing easy data management between devices and software version upgrades.

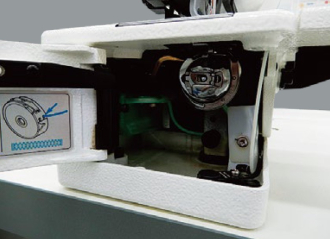

Hook oil level adjustment

With the latest LBH-1790AN head, the hook oil level can be easily adjusted by opening the hook lid cover and using the newly installed "hook oil level adjustment screw.

This eliminates the difficulty of maintenance work often associated with automatic machines.

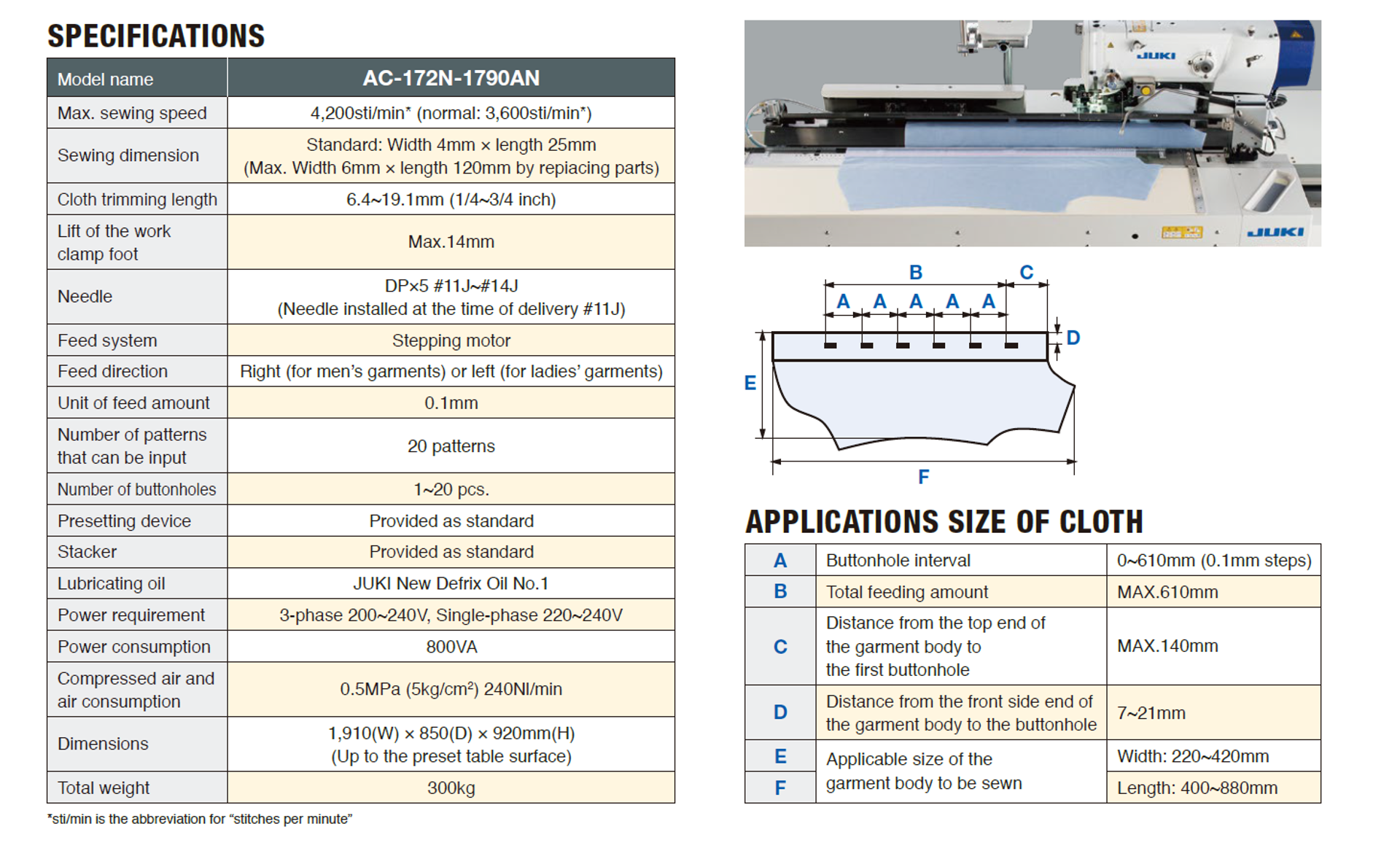

Specification