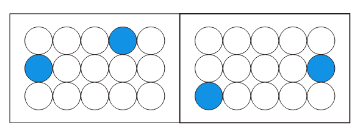

Realization of exhaustive testing

Before

Customer concerns

- There are variations in inspection quality in the sampling inspection.

- It may take some time depending on the level of skill of the inspector

- There is a possibility that defective products may be mixed in.

- Costs are incurred when defective products are generated or when complaints are made.

- When a bad occurs, it is difficult to identify the lot.

- Take time to prevent a recurrence

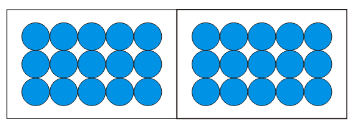

After

Customer feedback after introduction

- The generation of defective products was able to be suppressed by the inspection of all parts.

- Quality is improved, and it can respond to the severe quality of automobile-related and medical-related.

- Significant reduction in inspection time was achieved.

- Real-time detection of defective products enables quick feedback

- Identification of lots is possible even when bads occur.

- Quick measures to prevent recurrence of defective products can be taken even when defective products occur

Introduction example

| Before | After |

|---|---|

| Sampling inspection | Total inspection (50,000 pieces/month) achieved |