Faster inspection tact

Before

Customer concerns

- It takes a lot of man-hours to visually inspect multiple inspectors.

- There are variations in the appearance inspection results.

- It takes time to fill out and transfer the inspection results.

- Inspection time and man-hours are especially required for important safety parts where strict inspection quality is required.

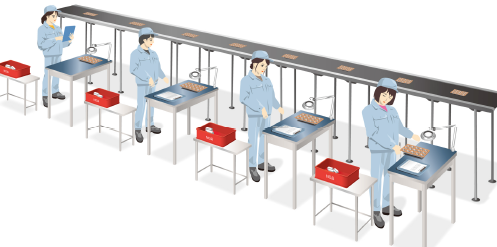

Line image before introduction of inspection machine

After

Customer feedback after introduction

- Reduced labor (reduced from 4 to 1)

- Inspection quality was improved by eliminating visual inspection.

- Line operation 24 hours a day, 365 days a year became possible

- Inlining of the testing process has enabled us to adapt to Industory4.0 and manufacturing 2025.

- Improvement of DX of the test results was achieved.

- Traceability was successfully established.

Image of high-speed in-line